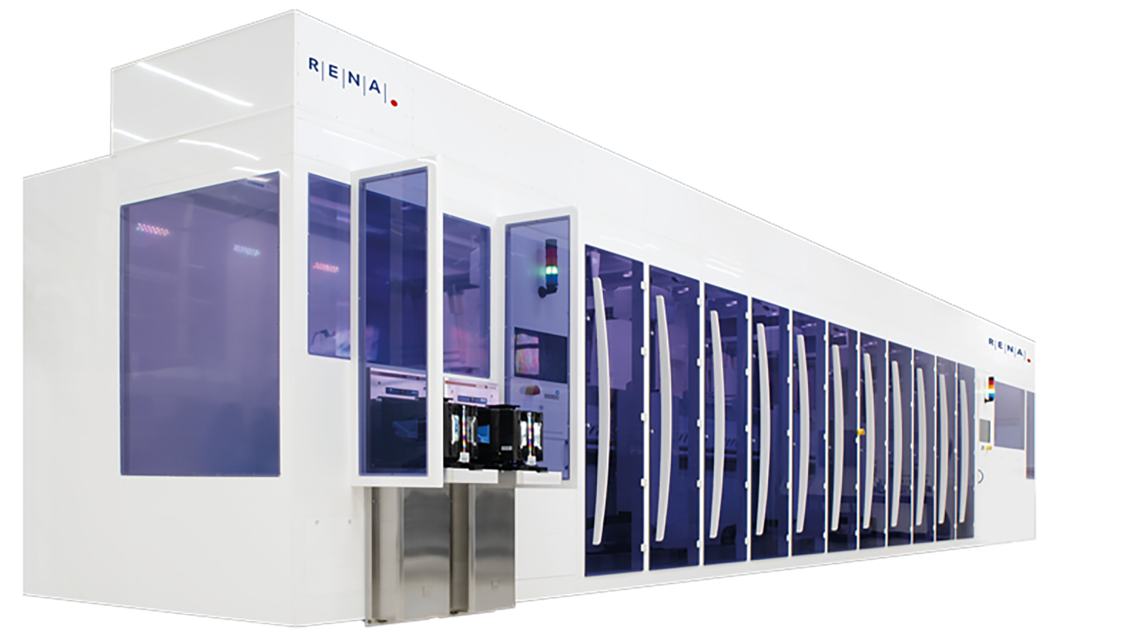

In the ever-advancing realm of semiconductor manufacturing, precision, throughput, and configurability are no mere preferences—they are essentials for competitiveness and innovation. At the center of these demands emerges Convergence, a state-of-the-art semiconductor wet processing tool for wafer processing in 200 mm and 300 mm fabs. Engineered in Germany and backed by proven in-house expertise across all subsidiaries, the Convergence represents the channeled know-how of RENAs wet-processing expertise from successful wafering, semiconductor and glass equipment.

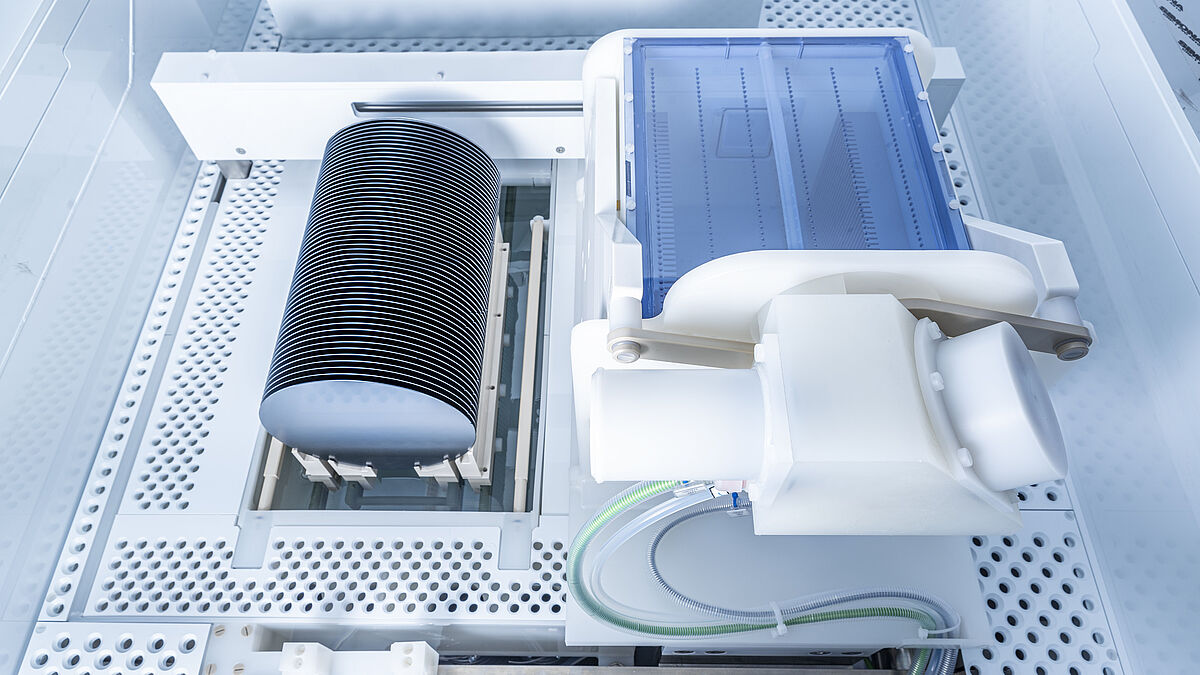

Carrierless Configuration Meets Full Automation

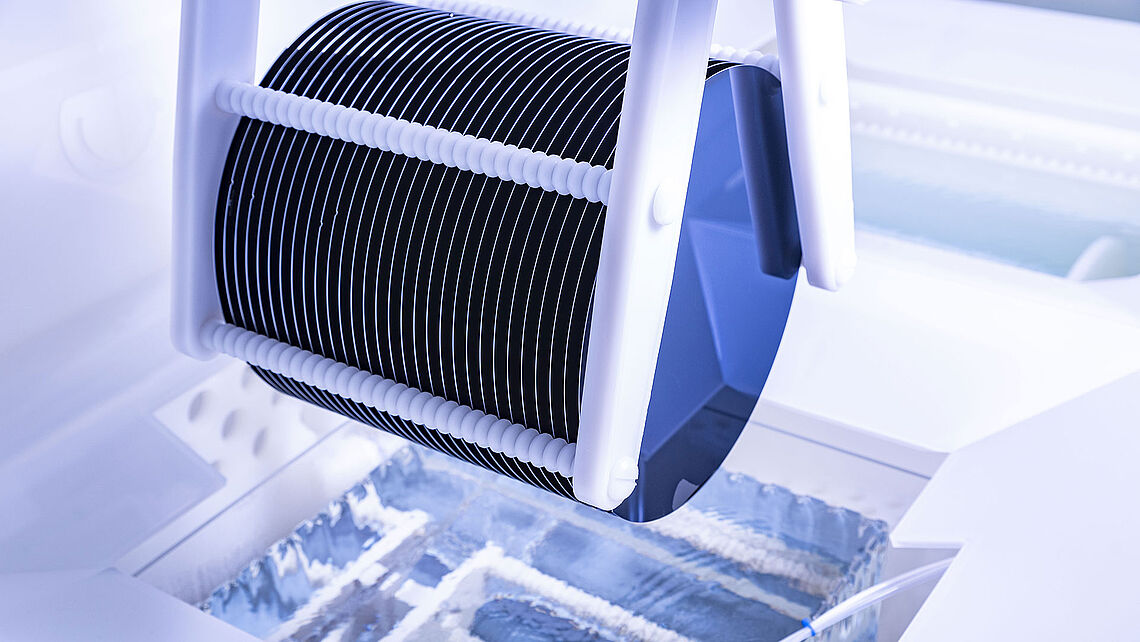

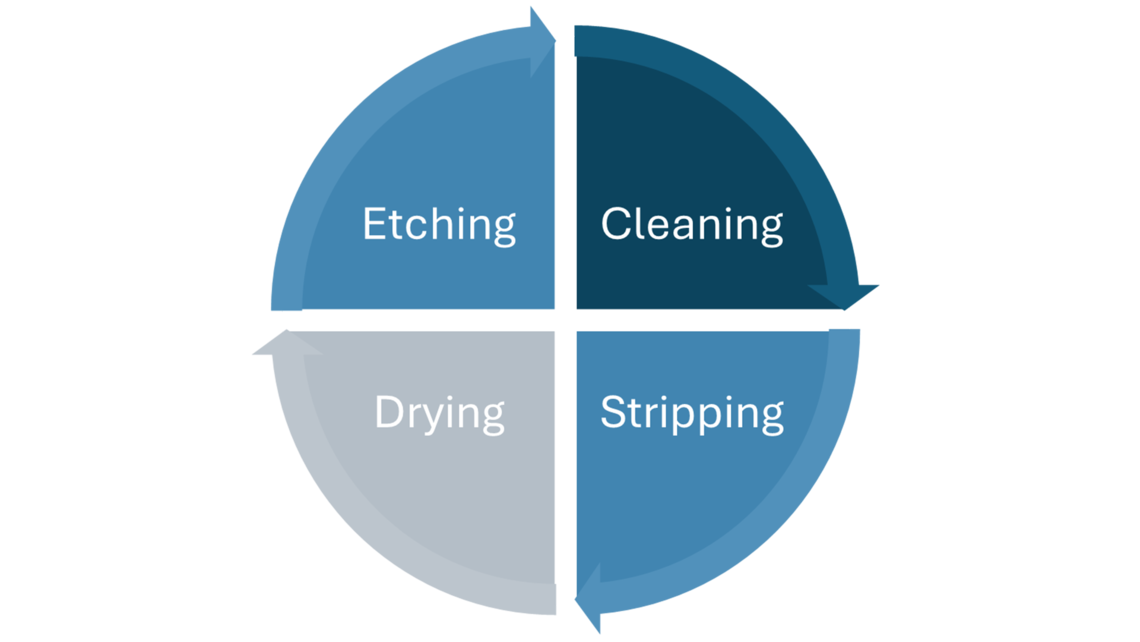

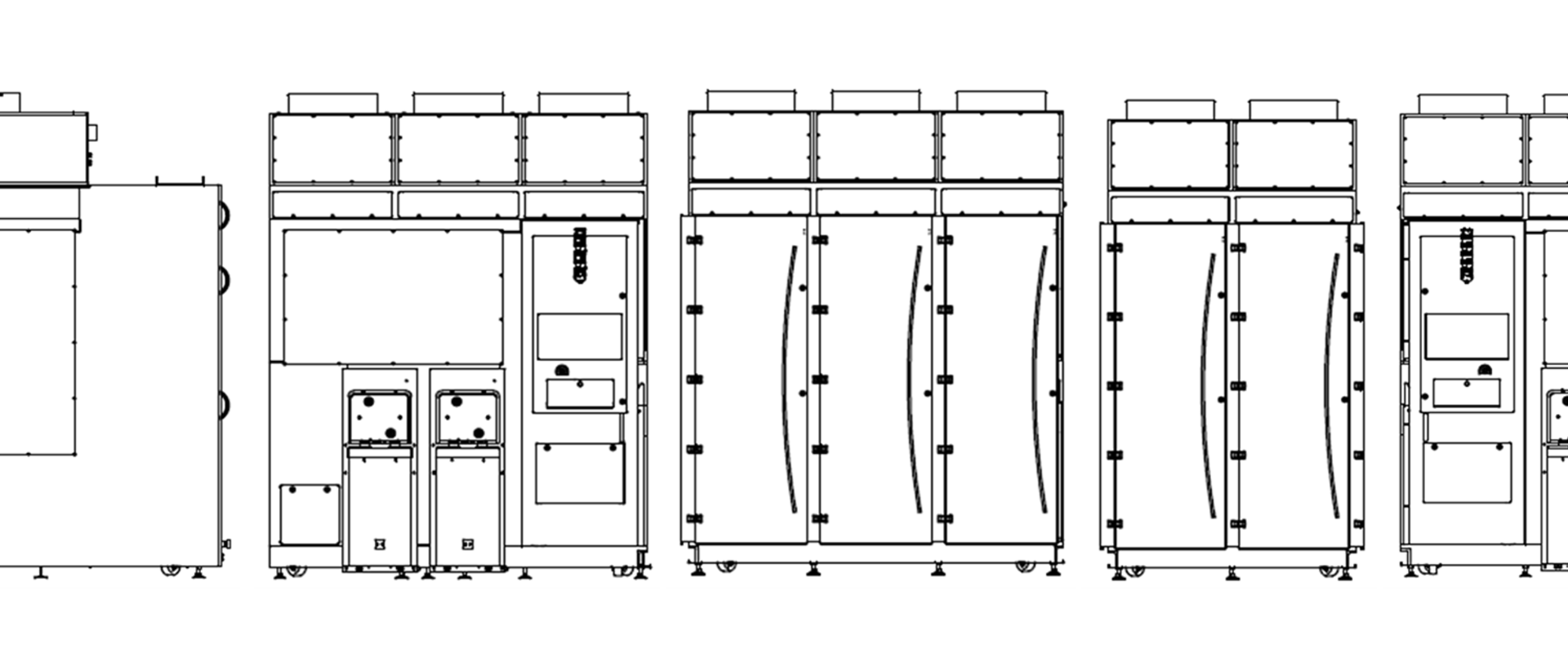

One of the standout features of Convergence is its carrierless process area, however low mass carriers can be used as well. This flexibility makes it ideal to adapt to diverse customer requirements and intricate process flows, while being fully integrated into the fab environment. This flexibility is supported by a modular design, enabling seamless tailoring of the Convergence for specific etching, cleaning, stripping and drying needs.

Optimized for Throughput and Homogeneity

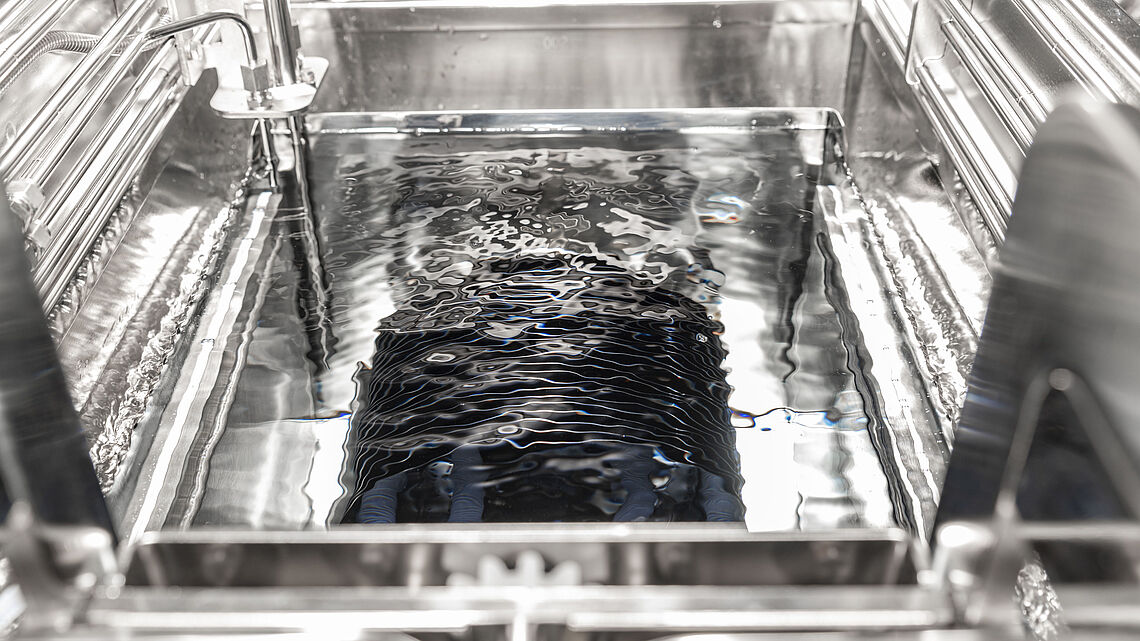

Efficiency is embedded in every corner of the system. With the capacity of up to process 100 wafers per batch Convergence ensures fabs can meet growing volume demands without sacrificing quality. The system delivers best-in-class homogeneity—both across individual wafers, wafer-to-wafer and batch-to-batch—crucial for consistent device performance and yield optimization.

Integration is key in modern fabs, and Convergence excels with full SECS/GEM compliance, facilitating seamless communication with factory automation systems. The system is supported by RENA’s proprietary in-house software, developed by a team of 50+ experts.

Safety and Service

in Every Detail

Convergence is built to uphold the highest safety standards, incorporating features such as cross slot detection to mitigate risks and protect valuable wafers. A service-friendly design minimizes downtime and facilitates rapid maintenance. Digital Service features are also available to support before the Machine has arrived, as well as during ramp-up or in case of support afterwards. The best technicians at your hand with minimal response time.

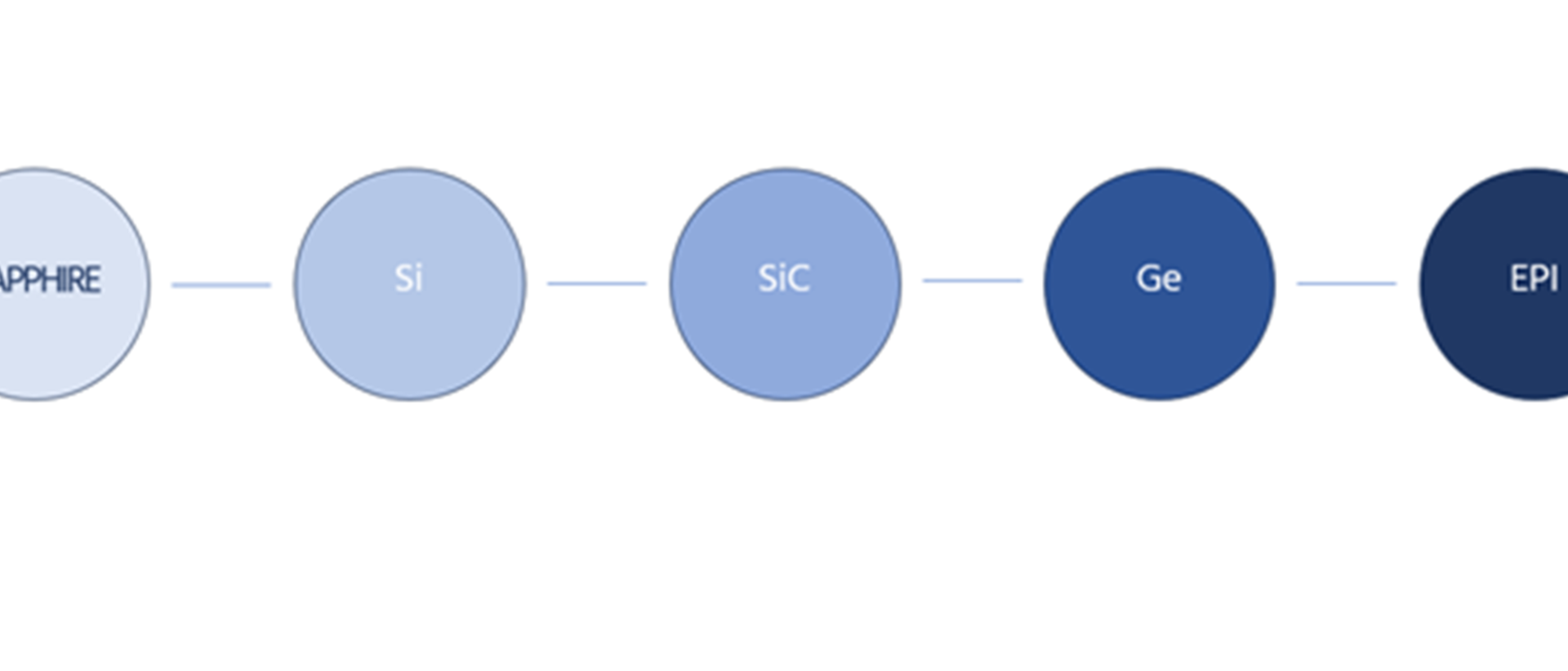

Versatility That Scales with Requirements

The system is available in etchant- and solvent-compatible versions for advanced applications in high-volume manufacturing. Convergence adapts to the customers needs without compromising its core strengths of reliability, safety, and performance. The modular concept offers plenty of flexibility suiting every need of the customers manufacturing facility. Whether it be throughput as the main focus or fab integration with standard or special interfaces—Convergence covers it all. The modular design makes it easy to fit in any producton environment.